Logo Making Rubber Keychain PVC Label Silicone 3D Patches Machine

Overview Products Show Application scenarios Products Description PVC product process flow diagram: 1, Mixing: According

Description

Basic Info

| After-sales Service | 1 Year |

| Warranty | 1 Year |

| Certification | CE |

| Condition | New |

| Customized | Customized |

| Automatic Grade | Automatic |

| Structure | Vertical |

| Keyword | Plastic Injection Mold Molding Services |

| Applicable Industries | Manufacturing Plant, Other |

| Product Name | PVC Rubber Patch Making Machine |

| Application | Production of PVC and Silica Gel Products |

| Marketing Type | Ordinary Product |

| Tiptop Sport Velocity | 40m/Min |

| Core Components | PLC |

| Voltage | 380V/220V |

| Power (Kw) | 10.5 |

| Applicable | Manufacturing Plant, Other |

| Cavity | Single Cavity\ Multiple Cavity |

| Material | Silicone |

| Work Colors | 12/16/20 |

| Transport Package | Wood |

| Specification | 60KG |

| Trademark | Gainjoys |

| Origin | China |

Product Description

Products Show

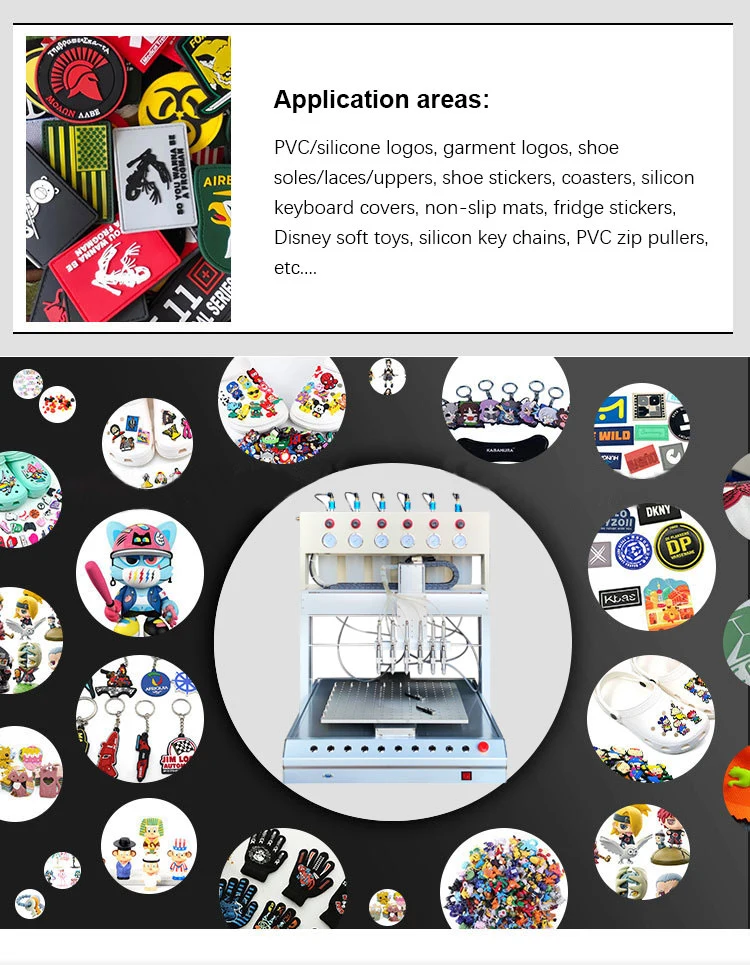

Application scenarios

Products Description

PVC product process flow diagram: 1, Mixing: According to requirements, according to a certain proportion of PVC materials, mixing evenly; 2, vacuum: The use of our special PVC vacuum equipment to remove bubbles; 3, dispensing: The PVC raw materials into the dispensing machine, 4, drying: After the injection molding table cut pieces into the energy-saving oven or baking mold table, its drying and shaping; 5, filling the bottom material: after the molding table into the automatic bottom material filling machine, 6,dry the bottom material: will fill the bottom material mold again into the energy-saving oven or baking mold table dryingshape; 7,complete: Cooling table take out the product, Trim and tear off the leftover material, the plastic part of PVC product isfinished.| item | value |

| Place of Origin | China |

| Condition | New |

| ProvidedVideo outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | 2022 New Product |

| Warranty of core components | 1 Year |

| Core Components | PLC, Bearing, Gearbox, Motor, Pressure vessel, Pump |

| Machine Type | Soft Rubber Injection Machine |

| Voltage | AC220V |

| Dimension(L*W*H) | 1340mm*1000mm*1500mm |

| Weight | 300 |

| Warranty | 1 Year |

| Power (kW) | 1.2 |

| Key Selling Points | easy learn and operate |

| Showroom Location | None |

| Applicable Industries | Manufacturing Plant, Other |

| Keywords | zipper pulls/label/keychains//fridge magnet |

| XYZ Spindle work precision | ±0.01mm |

| Work Colors | 12/16/20 |

| Name | 20 colour screw automatic dripping machine |

| Material | silicone |

| Tiptop Sport Velocity | 40m/min |

One-stop integrated service to make sure our customer get good products and good service.

1) Professional advice and rich experience help to choose machine.

2)Warranty time: All machines are guaranteed for one year.

3)Any problem: If you have any questions or any demands, we will reply you within 24 hours except the special reasons once you enquiry us.

4)Additives: installation book, Manual book, tool box will be sent with machine.

Q3. What are your payment terms?A3. TT in advance

Q4. What is the lead time ?A4. Generally if we have stock, we will deliver the machine in one week. If it need custom made, the lead time will be around 20-50 days which depends on the real situation. Q5. How does your factory control the quality?A5. Quality is very important, we take much attention to control our quality from raw materials to the end. We will test every machine before it leaves our factory to make sure it's working good. Our factory has passed CE, ISO, FAD. We also have audit periodically to make sure our products qualified. Q6. How long is the guarantee?A6. Our machine guarantee is for one year for no human damage factor. Q7. How should we do if we meet troubles while production?A7. About our after sale service, if any problems or operation questions, we will show you how to solve it or offer the suggestion accordingly. Also you can send the machine back for repairing or our engineer will go to check it.

Q8. How can I contact you for details?A8. You can click inquiry to contact us directly or email us.

Prev: High Speed Flat Bed Automatic Label Die Cutting Making Machine for Sale

Next: Good Price China Manual Pre-coating Thermal Film Laminating Machine

Our Contact

Send now